This is a scratch-built model of the Golden Age Racer "Art

Chester's Jeep, an US racing plane from the Thirties, which had

to compete with the - more famous and more dangerous - "Gee

Bees". The "Jeep" was quite a small plane with a

wingspan of about 17 feet. By the way, if anyone has pictures and

literature or knows of according sources regarding the full scale

airplane, I will appreciate every information!

It is based on a plan offered by the German modeling magazine

"FMT", but my

model is somewhat different, as I finally decided to power the

plane with an electric motor (originally I planned to fit an

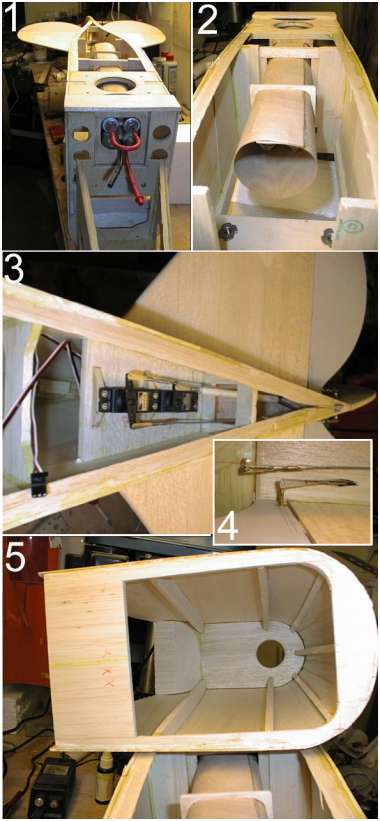

Webra 1.20). The equipment, consisting of a motor Ultra 3500-8

(Picture 1), 30 Sanyos 2000RC (Picture 2) and an according Schulze-controller (Picture 3), is bought already and

waiting for its incorporation...

The wing span is about 81", the weight should be not more

than approx. 13 to 14 pounds. This means, with a powerpack of 4.4

pounds in mind, that the airframe is to consist nearly just of

holes.

|

|

|

| Picture 1 | Picture 2 | Picture 3 |

|

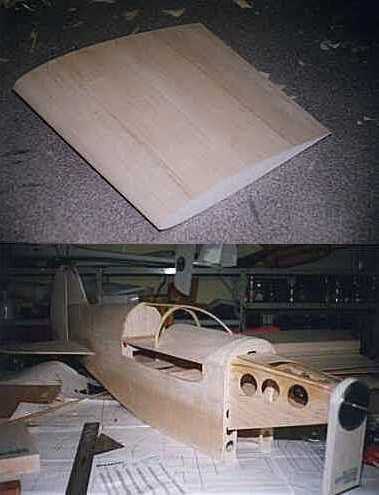

One of the four wing parts from

balsa-covered foam The core is made with a PC-controlled

cutting device, the airfoil is a NACA 2412. This is the fuselage (beginning of June '97). There are still some problems waiting for being solved...I hope, I made it further in the meantime. <g> |

|

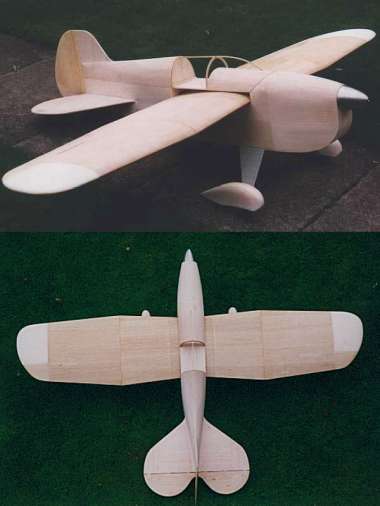

This is the status mid-July 1997. The balsa-cowling is ready (except finish, of course) and the still much too heavy undercarriage with "shoes" (also balsa) is mounted temporarily. I apologize for the pictures' poor quality. I'll do better taking them outside. If anybody has an idea rearding the canopy: I'll appreciate any suggestion! |

|

This is the Jeep in October. Unfortunately not as ready as it may look at first sight. The wing - already glass/epoxy-covered - lies loose on the fuselage, just for the foto. The wing tips are made from plain foam due to weight reasons. |

|

Some Details might be of interest. 1: the battery holder, made from 0.4 mm plywood, seen from the firewall. 2: ... and the same from behind. 3: servo installation in the elevator 4: the linkage in detail (the adjustable brass-horns are provided by Thommy) 5: the inside of the cowling. |

|

I am proud to report that I at

least succeeded in rounding the cowling and cutting its

openings... ;-) (and the wing fixing is also finished now) |

| Home |